Industrial Flooring

Our multi-purpose floor coatings include water-based and solvent-free epoxy, solvent-based polyurethane (PU), PU cementitious screed, and electrostatic discharge (ESD) systems engineered for applications ranging from light to heavy-duty use. Offering exceptional abrasion and chemical resistance, along with specialised performance features, our flooring solutions cater to a wide range of industries, from food-safe environments to large-scale warehouses.

Type of Industrial Flooring System

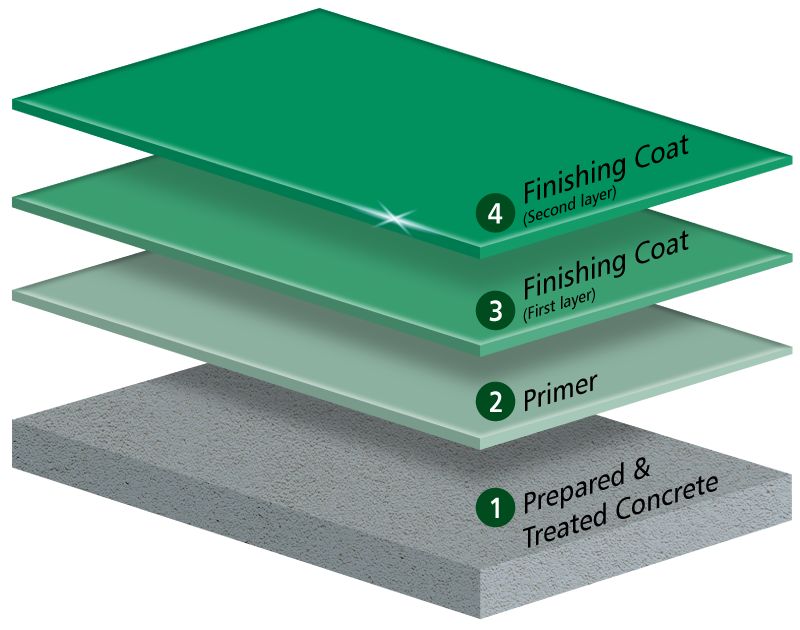

Prepared and Treated Concrete

Primer

FloorShield SF Epoxy Primer

- Solvent-free thus no solvent smell

- Low viscosity for penetration

- Excellent wetting of substrate

Finishing Coat

(First layer)

FloorShield SF Epoxy Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(Second layer)

FloorShield SF Epoxy Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

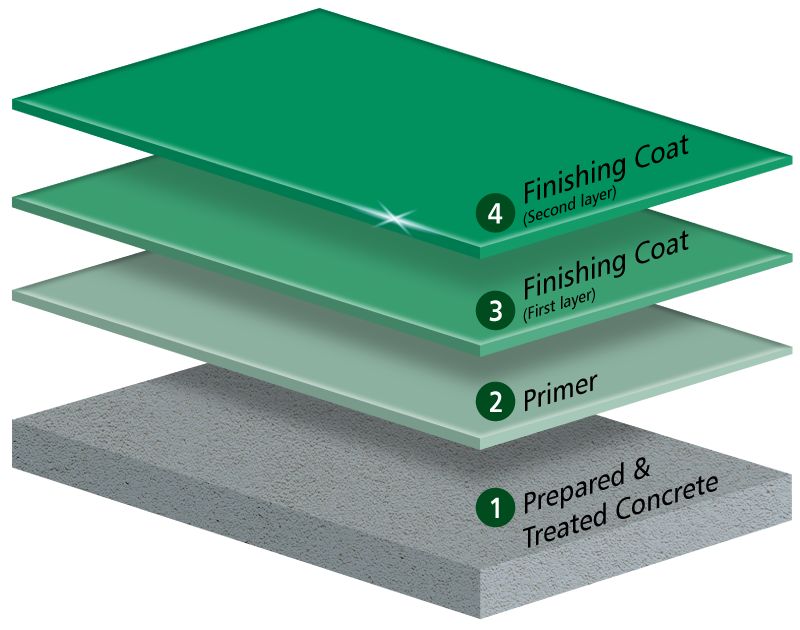

Prepared and Treated Concrete

Primer

FloorShield SF Epoxy Primer

- Solvent-free thus no solvent smell

- Low viscosity for penetration

- Excellent wetting of substrate

Finishing Coat

FloorShield SL1 / SL2 Epoxy Finish

- High gloss thus easy to clean contamination

- High impact and chemical resistance

- Seamless and dust-free

Note: Additional systems are available, including the Moisture Barrier System for basement and direct ground contact (moisture content >4%).

Recommended Areas

Overview Of Industrial Flooring Systems

| Moisture Barrier System | ||||

|---|---|---|---|---|

| System | FloorShield Solvent Free Epoxy System | FloorShield Solvent Free Self Levelling Epoxy System | FloorShield Solvent Free Epoxy System | FloorShield Solvent Free Self Levelling Epoxy System |

| No. of Coats | 3 | 2 | 5 | 4 |

| Total Thickness (mm) | 0.5 - 0.6 | 1.0 - 2.0 | 4.5 - 5.0 | 5.5 - 6.0 |

| Abrasion Resistance (ASTM D4060) |

< 80mg / 1000 cycles | < 80mg / 1000 cycles | < 80mg / 1000 cycles | < 80mg / 1000 cycles |

| Shore D Hardness (ASTM D2240) |

> 80 | > 75 | > 80 | > 75 |

| Compressive Strength (ASTM C579) |

> 85N/mm² | > 85N/mm² | > 40N/mm² | > 40N/mm² |

| Flexural Strength (ASTM C580) |

> 40MPa | > 40MPa | > 20MPa | > 20MPa |

| Adhesion Strength (ASTM D4541) |

> 1.5N/mm² | > 1.5N/mm² | > 1.5N/mm² | > 1.5N/mm² |

FloorShield Epoxy PU System

Prepared and Treated Concrete

Primer

FloorShield SF Epoxy Primer

- Solvent-free thus no solvent smell

- Low viscosity for penetration

- Excellent wetting of substrate

Finishing Coat

(First layer)

FloorShield SF Epoxy Finish

- Solvent free thus no solvent smell

- Abrasion resistant

- Chemical resistant

Finishing Coat

(Second layer)

FloorShield SB BU Finish

- Low viscosity provides excellent wetting and over-coating adhesion

- Highly abrasion resistance

- Excellent resistance to fuel, engine oil, and cleaning chemicals

Note: Additional systems are available, including the Moisture barrier system is available for basement/ direct ground contact (moisture content > 4%) to prevent paint bubbling and paint peeling.

Recommended Areas

Overview Of Industrial Flooring Systems

| Moisture Barrier System | |||

|---|---|---|---|

| System | FloorShield Epoxy PU System | FloorShield Epoxy PU System | |

| No. of Coats | 3 | 5 | |

| Total Thickness (mm) | 0.5 - 0.6 | 5.0 - 5.5 | |

| Abrasion Resistance (ASTM D4060) |

< 80mg / 1000 cycles | < 80mg / 1000 cycles | |

| Shore D Hardness (ASTM D2240) |

> 80 | > 80 | |

| Compressive Strength (ASTM C579) |

85N/mm² | > 40N/mm² | |

| Flexural Strength (ASTM C580) |

40MPa | > 20MPa | |

| Adhesion Strength (ASTM D4541) |

> 1.5N/mm² | > 1.5N/mm² | |

| UV Light Resistance | Excellent (Non-Yellowing) | Excellent (Non-Yellowing) | |

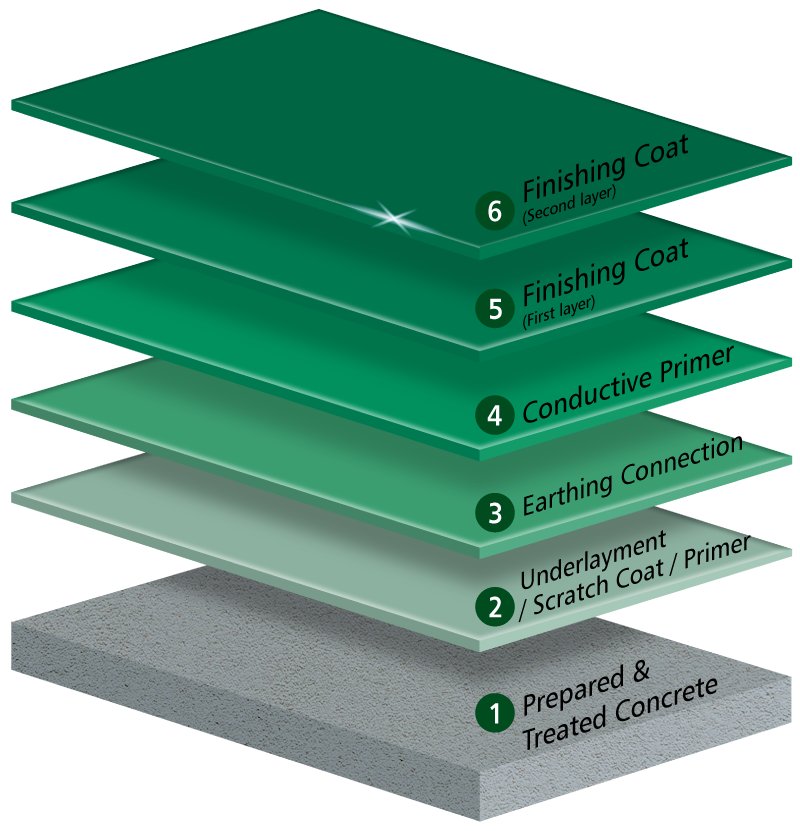

Type of Industrial Flooring System

Prepared and Treated Concrete

Underlayment / Scratch Coat / Primer

Earthing Connection

Finishing Coat

(First layer)

FloorShield ESD SF Epoxy Finish

- Electrostatic conductive

- High chemical resistant against wide range of chemical

- Abrasion resistant against medium traffic and trolley movement

Finishing Coat

(Second layer)

FloorShield ESD SF Epoxy Finish

- Electrostatic conductive

- High chemical resistant against wide range of chemical

- Abrasion resistant against medium traffic and trolley movement

Prepared and Treated Concrete

Underlayment / Scratch Coat / Primer

Earthing Connection

Conductive Primer

FloorShield ESD Primer WB

- Highly electrostatic conductive

- Good adhesion with concrete, and ESD topcoat

- Solvent-free, less odour

Finishing Coat

(First layer)

FloorShield ESD SF Epoxy Finish

- Electrostatic conductive

- High chemical resistant against wide range of chemical

- Abrasion resistant against medium traffic and trolley movement

Finishing Coat

(Second layer)

FloorShield ESD SF Epoxy Finish

- Electrostatic conductive

- High chemical resistant against wide range of chemical

- Abrasion resistant against medium traffic and trolley movement

Note: Additional systems are available, including the Moisture Barrier System for basements and direct ground contact (moisture content >4%), as well as ESD SL Epoxy Finish and ESD Ucreed MD (requiring a scratch coat before application) for various finishing coats. The ESD PU Finish is also available for exposed UV areas.

Recommended Areas

Overview Of Industrial Flooring Systems

| System | FloorShield ESD (Dissipative) |

FloorShield ESD (Conductive) |

|---|---|---|

| No. of Coats | 3 | 3 |

| Total Thickness (mm) | 0.5 - 0.6 | 0.5 - 0.6 |

| Surface to Ground & Surface to Surface (Earth) RG Spec (BS2050) |

1 x 10⁶ ohm to 9 x 10⁹ ohm | 1 x 10⁴ ohm to 9 x 10⁶ ohm |

| ANSI / ESD S-20.20-2007 | Compliant | Compliant |

| Decay Time through Human Body |

< 20s | < 20s |

| Human Body Voltage | < 100 volts | < 100 volts |

| Abrasion Resistance (ASTM D4060) |

< 5mg / 1000 cycles | < 5mg / 1000 cycles |

| Shore D Hardness (ASTM D2240) |

> 75 | > 75 |

| Compressive Strength (BS 6319) |

> 50N/mm² | > 50N/mm² |

Type of Industrial Flooring System

Prepared and Treated Concrete

Primer

AquaPrime Epoxy Primer (Red)

- Excellent bond strength to concrete surfaces

- Moisture tolerant to damp substrates during application

- Zero VOC and environmentally friendly

Finishing Coat

(First layer)

FloorShield Ucreed MD

(Scratch Coat)

- Excellent wear resistance and durable

- Resists micro-organism (bacterial, fungi, mold, mildew) growth

- HACCP Certified

Finishing Coat

(Second layer)

FloorShield Ucreed MD

(Scratch Coat)

- Excellent wear resistance and durable

- Resists micro-organism (bacterial, fungi, mold, mildew) growth

- HACCP Certified

Prepared and Treated Concrete

Primer

AquaPrime Epoxy Primer (Red)

- Excellent bond strength to concrete surfaces

- Moisture tolerant to damp substrates during application

- Zero VOC and environmentally friendly

Finishing Coat

(First layer)

FloorShield Ucreed MD

(Scratch Coat)

- Excellent chemical resistance

- High impact resistance

- Excellent wear resistance and durable

Finishing Coat

(Second layer)

FloorShield Ucreed HD

- Excellent wear resistance and durable

- Resists micro-organism (bacterial, fungi, mold, mildew) growth

- HACCP Certified

Recommended Areas

Overview Of Industrial Flooring Systems

| System | FloorShield Ucreed MD | FloorShield Ucreed HD |

|---|---|---|

| No. of Coats | 4 | 4 |

| Total Thickness (mm) | 4 - 7 | 7 - 13 |

| Abrasion Resistance (ASTM D4060) |

38mg / 1000 cycles | 83mg / 1000 cycles |

| Shore D Hardness (ASTM D2240) |

> 80 | > 82 |

| Compressive Strength (BS 6319) |

> 50MPa | > 50MPa |

| Flexural Strength (ASTM C348) |

> 20MPa | > 20MPa |

| Adhesion to Concrete (ASTM C158) |

> 1.5MPa | > 1.5MPa |

| Service Temperature |

5°C to 80°C (3mm) -5°C to 100°C (6mm) |

-15°C to 130°C (6 - 9mm) -40°C to 150°C (9 - 12mm) |

Further Information On Flooring Solutions

Download Official Brochure

Browse through more in-depth product information and solutions.

Contact us

We’re always here to help if you need any assistance on your projects.